Bill Of Materials What’s It, Example, Template, Sorts, Vs Boq

There are many several types of payments of materials and a few are unique to particular business sectors, as an example. As a point of reference, parent gadgets are upper-level assembly that contains items, which are lower-level parts needed to construct a parent item. It’s useful for estimating materials and costs, planning purchases, ensuring parts are available, and avoiding delays. By placing the finished product on the top, adopted by its individual components and materials, a BOM acts as a centralized supply of data. In the engineering section, an engineering BOM charts the course for design, whereas a manufacturing BOM guides the meeting course of. From large scale industries to small manufacturing units, having an in depth BOM reduces waste and ensures that assets are utilized effectively.

- Each sort offers a specific perspective on the product and is important for efficient planning, execution, and assist throughout totally different stages of the product lifecycle.

- A Invoice of Supplies (BOM) is a crucial document utilized in manufacturing, engineering, and stock management.

- Furthermore, when a BOM is integrated with a company’s enterprise useful resource planning (ERP) system, it offers prompt visibility into the manufacturing process.

- A manufacturing bill of materials (MBOM) is the most acknowledged kind and consists of all supplies, assemblies, formulation, or elements required to produce a shippable product.

- This example reveals how BOM finds relevance in each sector, together with enterprise and army setups.

What Are The Different Types Of Bom?

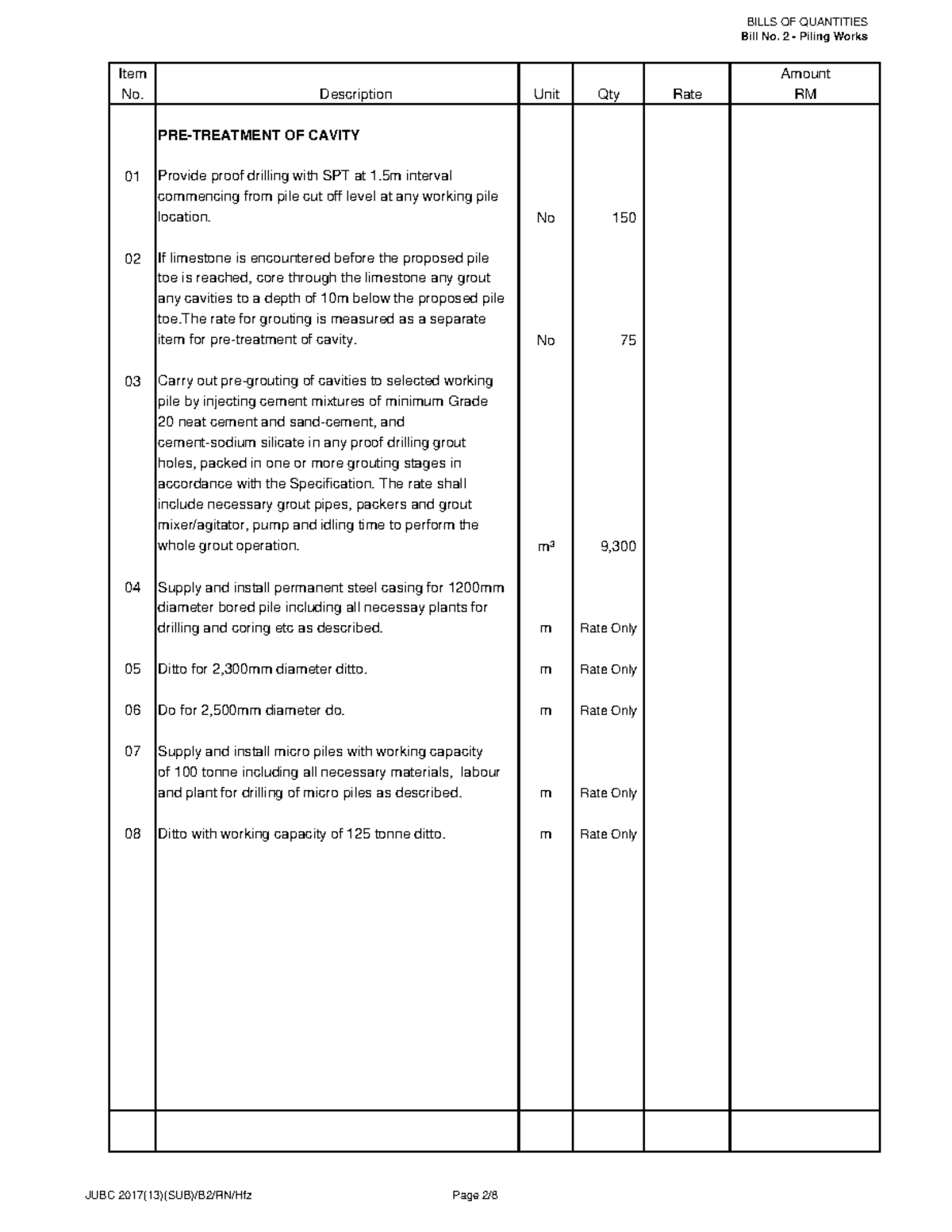

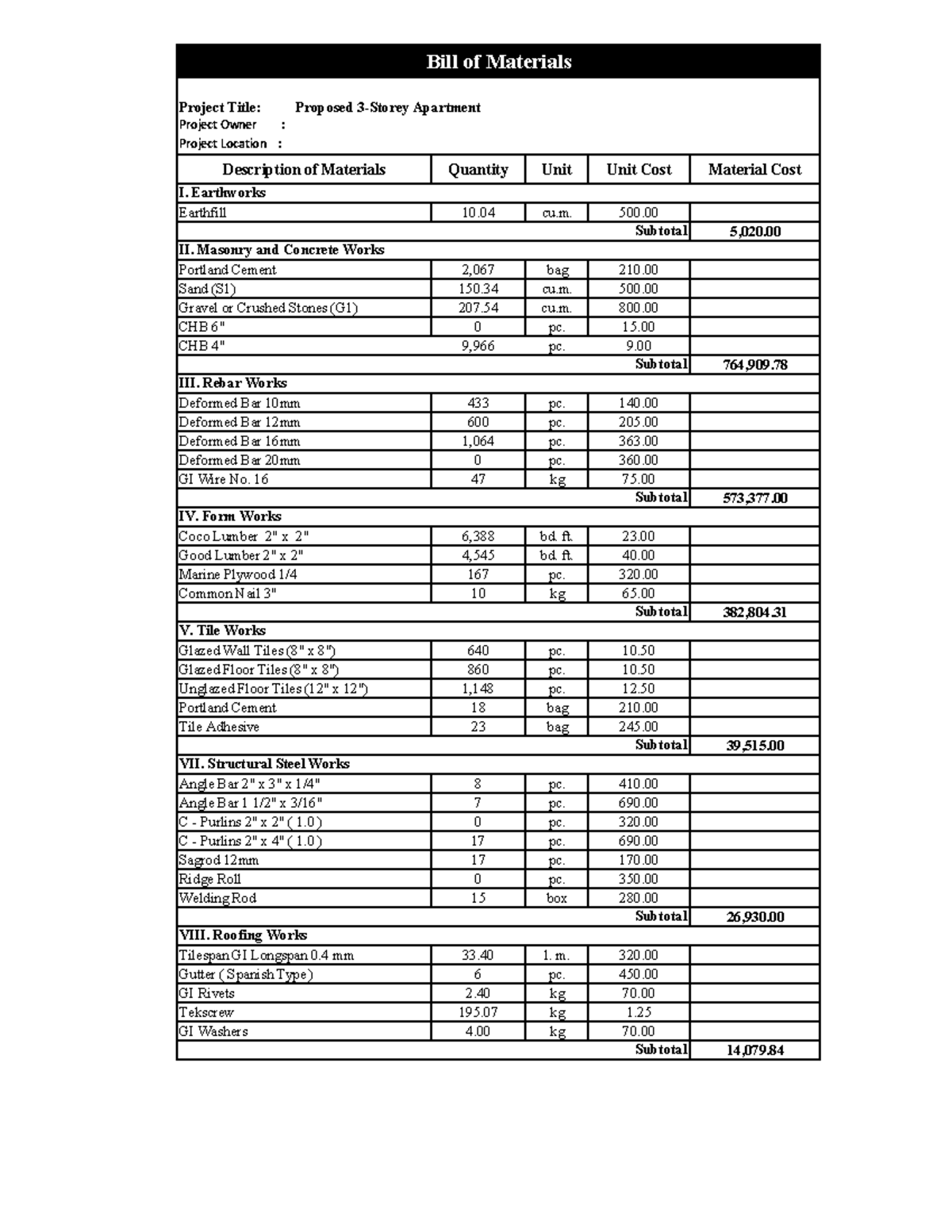

A bill of materials (BOM) is a report of all the components, materials, and processes required to fabricate a product. A BOM functions as a hierarchical listing detailing how a product is built. It shows the exact quantities of elements required for every stage of the meeting, from uncooked materials such as fastenings to sub-assemblies and packing materials.

This BOM is particularly helpful if a product has multiple iterations to manufacture and assemble (for occasion, totally different colours, sizes, or features). It lets you outline a base model and rapidly create variations based mostly on customer preferences to streamline the ordering and production course of. ✅ A structured BOM ensures that each staff speaks the identical language — making product planning, costing, and supply smoother and extra dependable. Whether Or Not you use pdf, spreadsheet, or cloud-based BOM, it ought to comprise correct information about what merchandise you should manufacture.

A well-defined BOM will let you know how a lot of every particular person half you should buy and when you want to make those purchases. Creating a exceptional product after weeks, months or years within the workshop is normally a thrilling expertise for an entrepreneur. Though it’s exciting to get a new product up and running, you’ll need to prioritize group throughout manufacturing and that features implementing a bill of supplies (BOM). Enterprise.com goals to assist enterprise owners make knowledgeable decisions to support and develop their companies.

Multi-level Bom

This creates a single information hub that simplifies access, maintains information consistency, and reduces errors from disparate spreadsheets or outdated documents. Tech giants corresponding to Apple and Google handle extremely advanced world supply chains and fast product innovation cycles. They record all components and assembles required to build a shippable product and organize these components within the actual order they’re used on the store flooring.

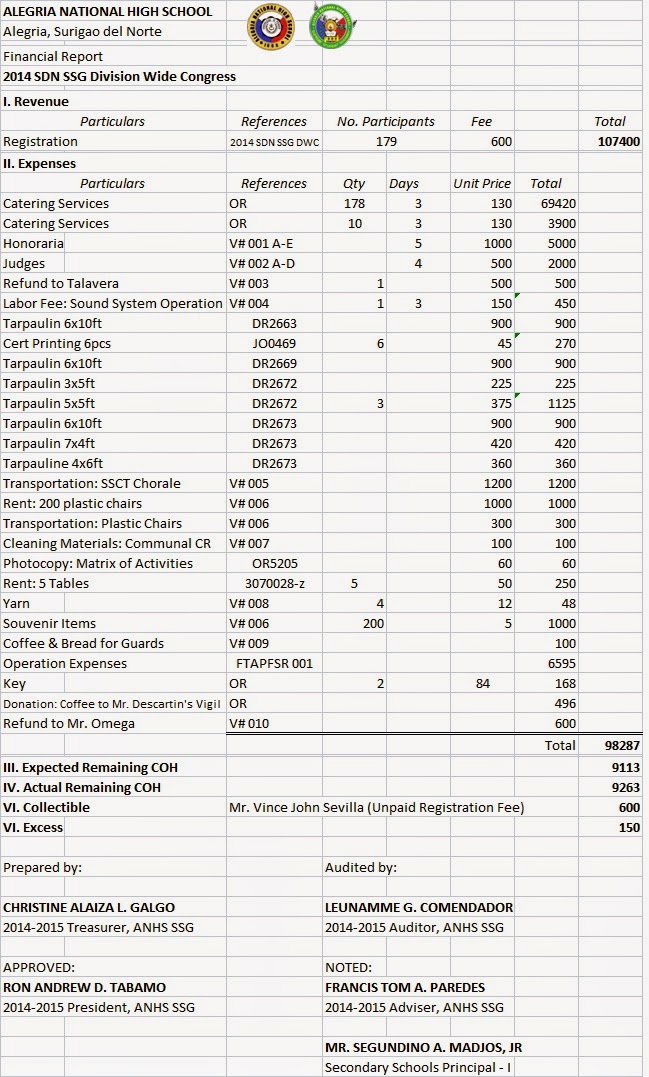

Leveraging the advantages and acknowledging the restrictions of BOMs helps organizations make informed choices about their implementation and management. If you are a small enterprise proprietor, an correct BOM will assist you to identify potential value savings, enhance profit margins, and make smarter monetary choices. In this text, we’ll dissect what exactly a BOM is, how different industries use BOMs, and share sensible tips to help your team handle them extra effectively.

Multi-level (or Indented Bom)

BOMs are not often static paperwork, particularly for products manufactured over prolonged intervals. When adjustments happen in manufacturing necessities or part specifications, these updates have to be reflected all through the BOM wherever that component seems. This ensures consistency and accuracy throughout the manufacturing course of while sustaining product quality and manufacturing efficiency. A invoice of materials (BOM) is a complete inventory of the uncooked supplies, assemblies, subassemblies, parts and components, in addition to the quantities of each needed to manufacture a product. In a nutshell, it’s the whole listing of all the items required to build a product.

In this article, we’ll clarify what bill of lading means in delivery and why it’s so vital for easy, worldwide logistics. More agencies and industries are beginning to require SBOMs in procurement, especially for high-risk techniques. Maybe better of all, the SBOM is pronounced S-bomb, so it really works for engineers who must deal with it and for the business fits which may get pleasure from saying it in board conferences. Most advocates on this space agree that we need this technology and we shouldn’t drop it… even if it’s hot. The key takeaway for Lieberman is that SBOMs aren’t just about assembly a compliance requirement. They are useful in understanding software composition, managing dependencies… they usually finally deliver software with higher confidence, velocity and management.

If you keep the materials and prices up to date in your BOM, it’ll be simple to track the final price of the finished product—and whether or not you’re not on observe. The single-level bill of materials is similar to a purchasing listing, the place every element of a product is listed once alongside the required quantity. This easy BOM format is ideal for smaller tasks or merchandise with minimal elements. Furthermore, when a BOM is integrated with an organization’s enterprise useful resource planning (ERP) system, it offers immediate visibility into the production process. This integration not solely streamlines the workflow inside ERP systems, but it also empowers managers with real-time updates, alerting them promptly about inventory shortages or the need for merchandise restocking. When it’s kept up-to-date and managed successfully, the BOM turns into an indispensable software for inventory control, sales order administration, and bettering the effectivity of the production process.

Jobs can be assigned with sturdy task lists that show the proportion accomplished. These are just a few of the advantages that make BOMs vital doc for any manufacturer, however there are heaps of other instruments you want to use for manufacturing management. ProjectManager, for instance, has Gantt charts, kanban boards, real-time dashboards and different https://www.simple-accounting.org/ tools that can assist with production planning, scheduling and management. Whereas it’d appear to be a comparatively easy format, utilizing a invoice of materials format helps you streamline numerous business processes to make your manufacturing operations extra environment friendly. Right Here are a variety of the key benefits you can get from utilizing a invoice of materials (BOM) format. Subsequently, the invoice of materials can be your central report of everything wanted to build your product.